HOW

to utilize

algae

COMPOSITION OF ALGAE-BASED MATERIALS

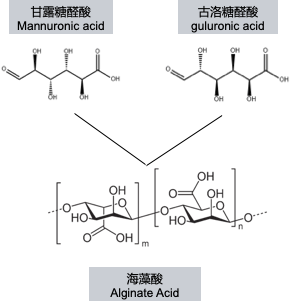

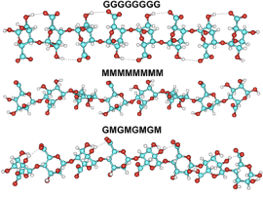

The production of algae-based materials primarily utilizes alginic acid in the cell wall of algae. Alginic acid is a kind of macromolecular carboxylic acid composed of mannuronic acid (M) and guluronic acid (G).

The chemical structure and physicochemical properties of alginic acid are mainly influenced by the species of algae and the extraction conditions. By applying modification technology, the properties and application efficacy of alginic acid can be enhanced. Through controlling technological conditions, alginic acid derivatives with a specific monomer structure and sequencing, branched-chain position, and degree of substitution can be prepared. This allows for the regulation of properties such as the solubility, hydrophilicity, and affinity for specific proteins of alginic acid bioproducts.

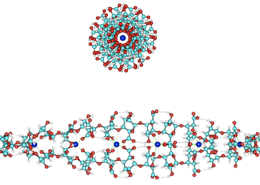

In the process of chemical and biological modification, covalent cross-linking can be employed to improve gel strength, chemical modification can be used to enhance the hydrophilicity of the main chain, and biological modification can be utilized to improve biodegradability. Thus, the application value of alginate can be effectively improved.